Through –hole soldering flexible—single point,drag,mini-wave or dip soldering

Exceptional accuracy and repeatable with near “zero defect “ soldering joint yields

Programming control and flexibility with computer software

Easy of operations, less handling,small footprint and durable construction

Main parts:

1. Solder pot nozzle

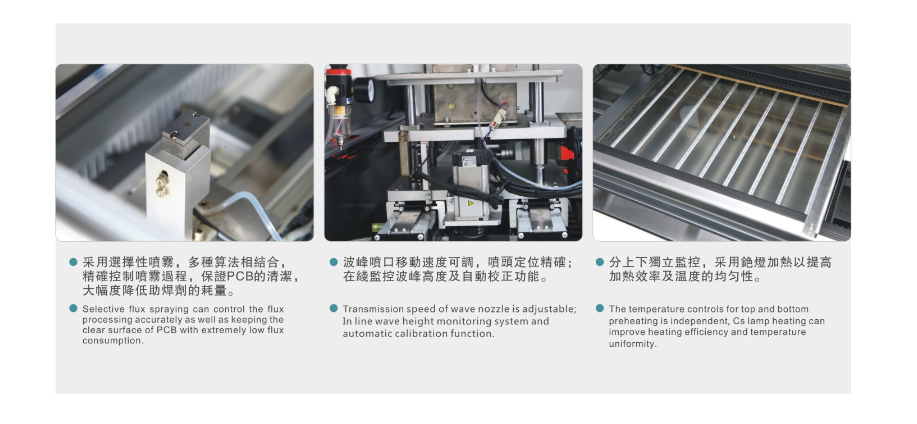

2. With a 130-micron orifice controlled by micro drop jet flux sprayer ( Made in Germany)

3. Preheating zone with flashing quartz IR preheater.

System Benefits & Features

• Precise, accurate, reliable soldering of through-hole components in mixed boards with previously soldered SMT components;

• Reduce board processing time as compared with hand soldering;

• Reduce direct labor costs, decrease rework costs, increase consistency over hand soldering through-hole components;

• One, all inclusive system - Flux, Preheat, and Solder

• PC software interface for easy on instrument setup, programming and parameter control

• Instrument programming flexibility and control over preheat, temperature, soldering dwell times, location, direction, and more...

• Off-line programming with photos can and Gerber import software for convenient machine setup

• Variety of Nozzles available for flexibility - Wettable and Specialty Nozzles

• Lead-free compatible.

Specifications

|

Items |

Description |

|

Model |

NP-350 |

|

Min.PCB size |

L 50mm * W 50mm |

|

Max.PCB size |

L 300mm * W 300mm |

|

PCB top side / bottom side clearance |

Max.Upper 100mm and bottom 50mm |

|

PCB process edge |

>4mm |

|

Boards handling system |

|

|

Conveyor system |

Chain conveyor |

|

Conveyor heights |

850+/-50mm |

|

Width adjustment |

60mm to 460mm |

|

Width adjustment accuracy |

+/-0.2mm |

|

Position accuracy above fluxer, preheater,and solder nozzle |

± 0.1mm (± 0.004”) |

|

Conveyor direction |

Left to right / right to left |

|

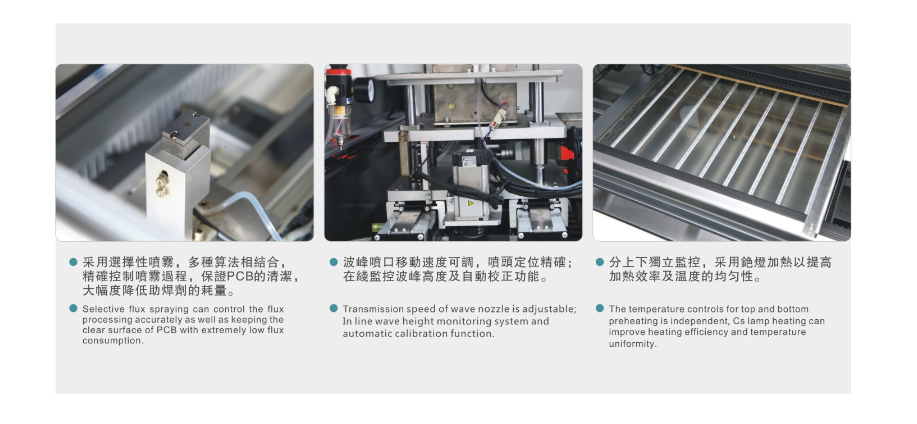

Preheating system – Bottom side |

|

|

Preheating temperature |

Max.180°C (PCB surface) |

|

Temperature control accuracy |

+/-2°C@3 sigma/Cpk≥1.33 |

|

Heater |

Philips Cesium light, independent control |

|

Fluxing system |

|

|

Fluxer nozzle |

micro drop jet fluxer |

|

Fluxing wet area |

Ø2 mm to Ø5mm |

|

flux types |

alcohol or water based |

|

Fluxing Controller |

automatic level control with capacitive sensor |

|

Selective position method |

X-Y Platform |

|

Position speed/ accuracy |

Max.400mm/s , +/-0.25mm |

|

Flux tank |

3L Stainless Steel & Fittings,including Flux Level Montiorin |

|

Soldering Unit for Soldering Processes |

|

|

solder pot compatible for lead free soldering |

Standard |

|

Min. Neighbor Component Clearance* |

1.5 - 3mm (0.06” - 0.12”)depending on nozzle type |

|

nitrogen operation |

Standard |

|

automatic wave height and solder level control |

Standard |

|

automatic wire solder feeder |

Standard |

|

wettable and non-wettable quick change nozzles |

Standard |

|

solder bath temperature |

300°C |

|

Temperature control accuracy |

+/-2°C@3 sigma/Cpk≥1.33 |

|

Solder pot capacity |

12kg lead free |

|

Wave heights |

Max.5mm |

|

Solder pot moving speed |

Max.400mm/s |

|

Soldering nozzle dimensions |

Ø5 to Ø12mm (or customized) |

|

Control system |

|

|

PCB data import |

GERB file, Offline file import, Image program |

|

Programing interface |

Windows interface |

|

Power |

220 VAC, 1Ø, 15A |

|

Power max.consumption |

2.5kW |

|

Max. Fuse Rate |

15A |