|

Model |

HS-0601 |

|

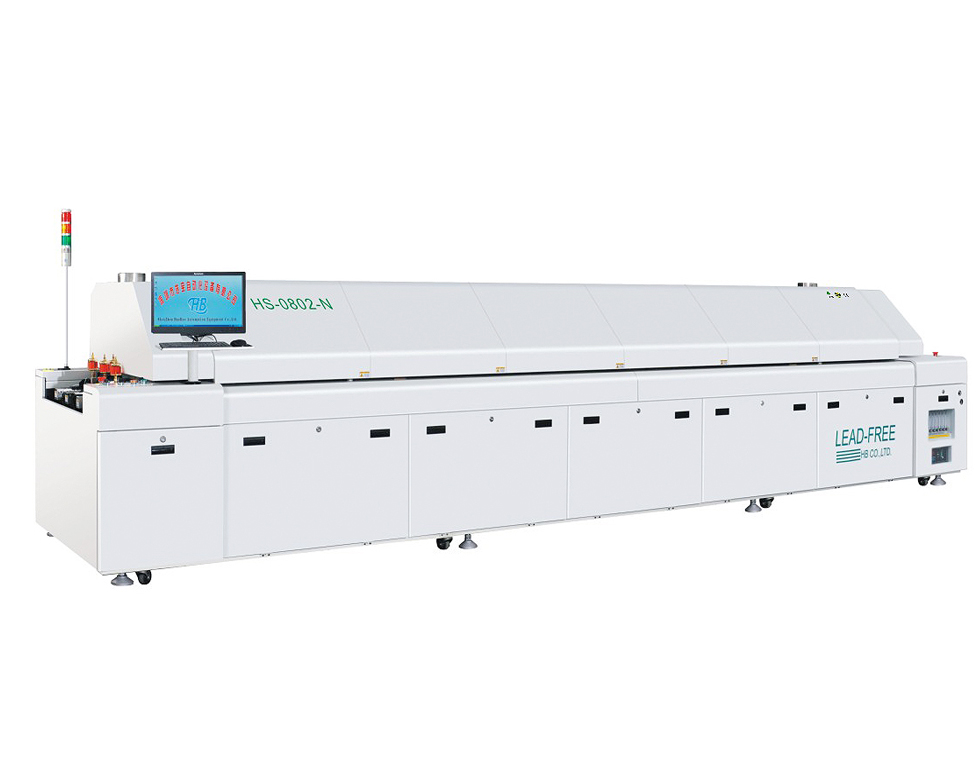

HS-0802 |

HS-1002 |

HS-1202 |

||

|

Dimension(L*W*H)mm |

3600*1383*1490 |

|

5310*1353*1490 |

6100*1353*1496 |

6915*1353*1496 |

||

|

Weight (kg) |

1325 |

|

2200 |

2400 |

2600 |

||

|

Number of heating zones |

Top 6+ bottom 6 |

|

Top 8+ bottom 8 |

Top 10+bottom 10 |

Top 12+bottom 12 |

||

|

Length of heating zones(mm) |

2359 |

|

3121 |

3891 |

4706 |

||

|

Number of cooling zones |

Top 1 Forced air cooling |

|

Top 2 Forced air cooling |

|

|

||

|

Nozzle plate |

8 mm Aluminum alloy plates |

|

|||||

|

Exhaust volume |

10M2/min *2 channel exhaust |

||||||

|

Control system |

|

||||||

|

Power supply requirements |

3 phase ,380V 50/60Hz ( optional : 3 phase ,220V 50/60V) |

||||||

|

Total Power |

52KW |

64KW |

80KW |

92KW |

|||

|

Startup power |

26KW |

28KW |

34KW |

38KW |

|||

|

Normal Power consumption |

7KW |

|

9KW |

10KW |

11KW |

||

|

Warming time |

< 15mins |

|

30 minutes |

|

|

||

|

Temp. setting range |

Room temperature to300°C |

Room temperature to 300°C |

|||||

|

Temperature control method |

PID Close loop control +SSR Driving |

||||||

|

Temperature control precision |

+/- 1.0 °C |

||||||

|

Temperature deviation on PCB |

+/- 1.5°C ( by HB test standard ) |

||||||

|

Conveyor system |

|

|

|

|

|

||

|

Chain structure |

Single buckle |

Single buckle for preventing board jammed |

|||||

|

Max. PCB width |

400mm |

400mm ( Optional 610mm ) |

|||||

|

Range of rail width |

50-400mm |

50mm -400mm (optional 50mm -610mm ) |

|

||||

|

Components clearance |

Top/Bottom clearance of PCB : 25mm |

||||||

|

Conveyor direction |

L to R ( Optional R to L ) |

||||||

|

PCB transmission method |

Chain + Mesh |

||||||

|

Conveyor speech |

300mm /min-2000mm / min |

||||||

|

lubrication |

Auto-lubrication + Manual-lubrication |

||||||

|

Optional |

Full N2 system, Center support system ,KIC RPI reflow process inspection ,Dual lane |

||||||